Some of the barriers are: duplicate files, properties spread around, unresolved models, uncategorized files, lack of planning and lack of Vault knowledge.

So, let’s break it down.

Duplicate filenames

When sending data to ERP or sending metadata from a file, the metadata is based on files that are selected, or if it’s an Inventor assembly it’s based on the BOM. If there are then duplicate filenames for different files, this will create quite a mess in the ERP system. Solutions could be to either create duplicates of the same file, or we add different files with the same metadata. It needs to be cleaned and taken care of.

Properties

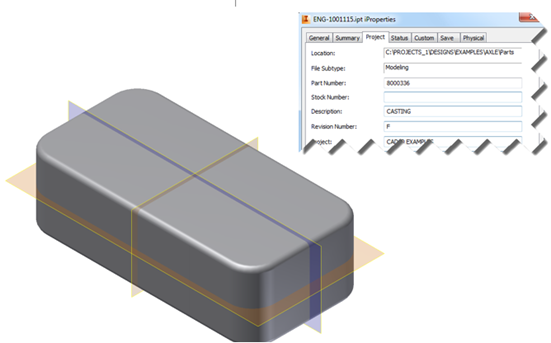

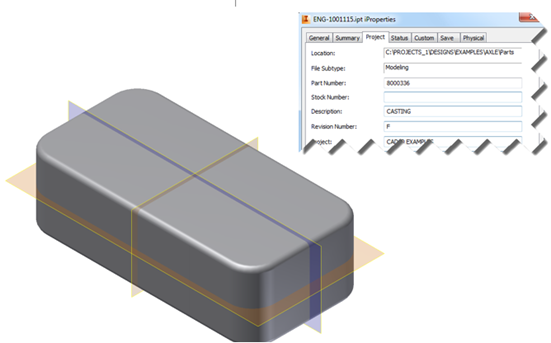

Sending metadata (Properties) into the ERP system reveals sometimes that the metadata resides on different properties in the files. This can be checked with Vault before data is sent to ERP – with Sovelia Vault this is even easier as you can just move the metadata to the correct property during the export process.

Unresolved models

Sometimes drag and drop functionality has been used on moving CAD files, and as a result files are missing in Vault. Those models are then unresolved, and users commonly select to skip this every time they open it, as they might not know how to fix this problem. This might sound surprising, but it’s not unusual. Again, data can’t be sent to ERP before the model is resolved.

User knowledge

Training and upgrading users’ knowledge level by sharing information regularly during ERP projects is how they understand what is happening in Vault and the issues they see when working with data. Equally important is to train users and agree what should be stopped doing, and what to start doing to make the Vault - ERP integration work seamlessly.

Feels like a lot to do?

It can be a lot, yes, but with the right experience and tools available from many similar projects, these tasks are set to succeed. Our Sovelia team usually participates in the meetings with the company’s ERP supplier and the customer to understand and agree what data to send and where. The ERP supplier’s knowledge is of their solutions, whereas CAD and PDM solution knowledge and integrations are core to Sovelia and Symetri’s offer.

Co-operation also minimizes unfavorable workflows in the integrations caused by too little knowledge. For example, some ERP suppliers could say that the company needs to use the Item master in Vault, but that is not actually necessary. Sovelia Vault can send directly from the CAD BOM on events in the Vault. As an example, when a file is released would be a good point to send data from Vault to ERP as the BOM can be checked for consistency, and if needed, deny the release unless all data is complete and compliant.

Often, the most time-consuming task is getting the old Vault and CAD files ready to transfer correct data, but when Vault is in order, the configuration of the ERP export is a simple task using Sovelia Vault.

Börre Hartviksen, Sovelia Vault Product Manager

How to prepare for an ERP integration

With the right expertise and Sovelia solutions, the transition from excel and manual typing into a safe and consistent workflow is straightforward, but requires some “elbow grease”.

First:

Item data starts from the smallest component in a BOM and all components need to be defined properly. Make a plan for metadata and map properties in a Table to plan the integration.

Example table.

|

Filetypes

|

File Property

|

Drawing Title Block

|

To ERP

|

|

ipt

|

Part Number

|

Drawing Number

|

Item Number

|

|

ipt

|

Title

|

Title

|

Title

|

|

ipt

|

Description

|

-

|

-

|

|

iam

|

Part Number

|

Drawing Number

|

Item Number

|

|

iam

|

Title

|

Title

|

Title

|

|

iam

|

Description

|

-

|

-

|

|

ipn

|

-

|

-

|

-

|

|

idw

|

Part Number

|

Drawing Number

|

Item Number

|

|

idw

|

Title

|

Title

|

Title

|

|

idw

|

Description

|

-

|

-

|

|

dwg

|

Part Number

|

Drawing Number

|

Item Number

|

|

AutoCAD dwg

|

Part Number

|

Drawing Number

|

Item Number

|

Start adding metadata (properties) to files as soon as you have decided what data to send to ERP and create workflows for the cad users and describe it in a manual for everyone.

Then, as mentioned before, data in Vault needs to be cleaned up; exporting data, cleaning it up, adding missing data and importing it back again. The operation is easy, but again, the job to add missing data often requires some manual work.

If the plan is made thoroughly, work is done methodically and the knowledge and experience available is used, you will succeed with as little pain as possible. Tools or software alone can’t solve the issues; knowledge and good workflows are always needed.

Hopefully you’ve got some inspiration and we’re looking forward to hearing back from you!