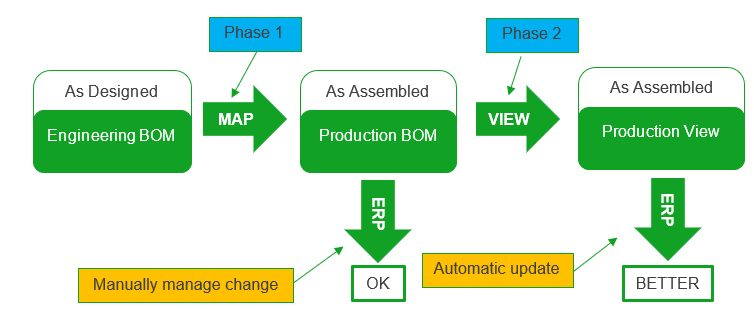

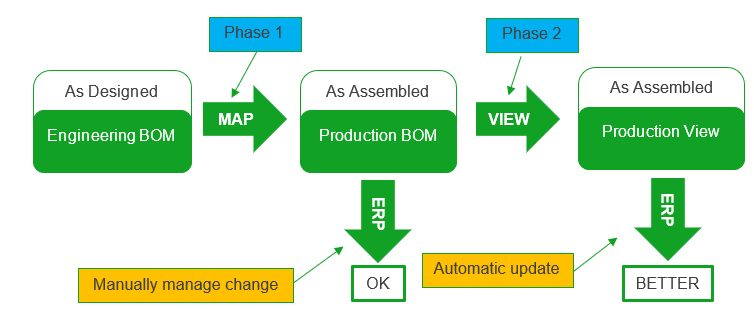

Production Process planning from Sovelia Core perspective is the action of mapping between the two environments. Component Assignment is sometimes another way of describing this and is also sometimes a task that the ERP system may perform. ERP tools tend to be more complexed to use and don't automatically update if the engineering BOM changes. There can be many different phases in the production process that need to be mapped to the Engineering BOM. A question to ask: Is this item in the Engineering BOM part of the Production process and is it relevant?

Then taking this process one step further we can look at the Production View inside Sovelia Core and seamlessly export the information to your ERP system.

Want to start a challenging conversation within your organization?

- Do production currently use your CAD data?

- Are production documenting their processes?

- Do production want to reorder the "as designed" information?

- Do you want to track production information automatically in ERP?

Examples of how Sovelia Core Production Process planning helps you

- Capture production process order

- Export production process information automatically to ERP

- Change the Engineering BOM and the production view allowing ERP information to update automatically.

- Specific tools for the production process planning team.