Sovelia Core

Dekati relies on Sovelia Core PLM system for a seamless flow of information from design to production

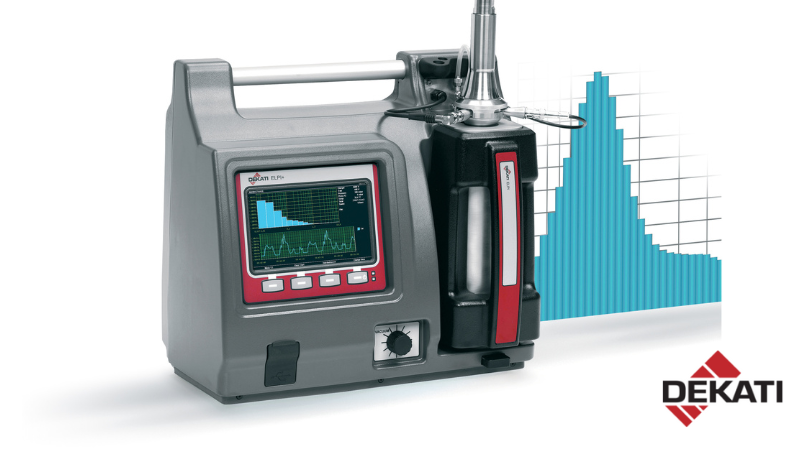

Dekati Ltd. has successfully designed and manufactured high-quality instrumentation for fine particle measurements for 30 years. Their products are meticulously developed and manufactured in Finland, adhering to the certified ISO 9001 quality standard and backed by a warranty of up to five years. Utilizing technology safeguarded by international trademarks, Dekati's instruments and sensors have a global presence, with representatives in nearly 40 countries and a customer base of thousands worldwide.

Dekati's success lies in its’ products impeccable quality, durability, and functionality across diverse measurement conditions. Achieving high-quality products necessitates smooth collaboration between design and production, ensuring everyone can access up-to-date information when needed. At Dekati, their skilled professionals uphold this seamless coordination with Sovelia Core PLM system.

Challenges in manufacturing: Fragmented data, manual version control, and the potential for human error in information flow

Manufacturing companies often face similar challenges in managing product information. Issues such as fragmented data, manual version control, and the potential for human error in information flow can lead to production errors or, in extreme cases, defective products reaching customers.

According to Ville Niemelä, who leads Dekati's R&D department, the necessity for digital product data monitoring arose from these challenges in product data management. Before implementing the PLM solution, Dekati stored product information, design versions, and iterations on individual designers' machines or in hardcopy, which meant considerable manual effort to produce and share materials for production.

Despite relatively smooth cooperation between the design and production departments, the manual information management led Dekati to seek process harmonization. The goal was to ensure that everyone involved in designing and manufacturing products had access to the latest information required for production.

"The Sovelia Core solution has streamlined our production information flow. For instance, when a product requires a specific pump type, our production team can instantly find details like the exact model, manufacturer, and type of that pump under the pump information." Ville Niemelä, R&D Director at Dekati

Choosing Sovelia Core was an easy decision

Continuous discussions about a PLM system for centralized product information were ongoing within the company regularly. However, a pivotal moment occurred when a new production manager, experienced in implementing PDM systems in the manufacturing sector, joined Dekati. This individual had a vision of how to implement the PLM project and what goals it aimed to achieve.

The most critical criteria for selecting a suitable PLM system for Dekati were smooth integration and support for the 3D design system. Ville Niemelä highlights that they chose Symetri's Sovelia Core because of its’ versatile features and the comprehensive support provided by Symetri.

Unlocking time-efficiency, seamless operations, and enhanced process efficiency

Sovelia Core has significantly enhanced Dekati's product design management, fostering stakeholder collaboration and smoother business operations. Sovelia's search tools enable swift and reliable retrieval of titles and documents. For example, designers can now access all drawings and parts lists related to the primary assembly with a single command.

Now, essential product documents are easily accessible as all necessary information is in one location. Product designers can monitor product status and titles effortlessly, marking them as design-ready or approved for production. Sovelia also ensures that the company's strict requirements for document quality and consistency are met, and only up-to-date and approved part lists and drawings are transferred to production.

"The satisfaction within our production is exceptional. There is no longer uncertainty regarding changes, particularly when launching new products. Sovelia Core removes uncertainty by ensuring that everyone, not just select individuals, can see on-screen which drawing is approved for production." Ville Niemelä, R&D Director, Dekati.

PLM: Just the start of Dekati's digitization journey

For Dekati, the implementation of Sovelia Core marks the initial step in modernizing their design and production processes. The company remains committed to ongoing internal optimization through digitization, aiming to save time and enhance data and project consistency.

At Dekati, it has been noticed that Sovelia Core has many features whose potential has not yet been fully utilized within the company. Discussions about acquiring Sovelia Core add-ons are underway, signaling their eagerness to explore further possibilities.

"I'm confident Sovelia Core's features are never-ending." Ville Niemelä, R&D Director, Dekati.

Next, Dekati is facing the integration of an Enterprise Resource Planning (ERP) system into the PLM system, allowing Dekati to optimize the entire product lifecycle management, from process design to production and delivery.

Dekati is known for its quality and ability to produce solutions for highly demanding measurement conditions. It aims to remain a pioneer in its field and recognizes the importance of cutting-edge technology investments and strategic partnerships in supporting growth and expertise.

"The investment in the PLM system truly pays off. It's completely revolutionized how we manage production at Dekati, offering us unparalleled control and systematization. Plus, it gives us the confidence to proudly show to our customers and partners how our production information flow and management operate." Ville Niemelä, R&D Director, Dekati

Challenges

- The company did not have a uniform operating method for data processing.

- There needed to be a unified storage location for materials.

- Finding the correct information at the right time was a challenge.

- Ensuring the latest version is time-consuming.

- Challenges existed in communication between designers and production.

- There was a possibility of errors in the data flow.

- Change management was time-consuming.

- There was a need for effective product life cycle management.

Solutions

- The Sovelia Core product information management system was optimized to suit Dekat's operations

- Secure storage and editing of design documentation

- Intelligent and scalable management and editing of product and delivery structures

Benefits

- Time and effort are saved when all product information is displayed in one system

- The risk of human errors is reduced

Designers' working time freed up for actual design work - Review and approval of plans made easier

- Information available via the web interface for mobile devices

- Plans can also be viewed automatically as 3D models

- Product documents are easily accessible when all product information is stored in the same place

- History of orders accurately stored in one place and easily accessibl

About Dekati

Dekati Ltd. is a world leader in designing and manufacturing innovative fine particle measurement solutions. They have nearly 30 years of experience providing measurement instruments and complete measurement solutions to various environments and sample conditions. Dekati has official representatives in almost 40 countries, and its customer base includes thousands worldwide. All Dekati® Products are developed and manufactured in Finland under a certified ISO 9001 quality system and are available with up to a five-year warranty.