Top 10 benefits of PLM software

1. Increased efficiency and productivity

One of the most significant benefits of PLM software is its ability to improve operational efficiency. By centralizing product information, PLM ensures that employees spend less time searching for data and more time on value-adding tasks. Features like automated workflows and real-time data sharing streamline operations, making cross-departmental collaboration seamless.

For instance, engineers can spend less time helping other departments find the correct product information and focus on actual design and innovation work. By standardizing processes and automating routine tasks, teams can work smarter, not harder, maximizing their productivity across the board.

2. Higher quality products

PLM software significantly reduces errors by minimizing manual work and human intervention in critical processes. Systematic change management ensures that all modifications are properly tracked, reviewed, and implemented, leading to consistently high-quality end products. The system maintains a clear record of all quality-related decisions and changes, making it easier to identify and address potential issues before they affect the final product.

PLM enables better documentation and adherence to regulatory standards, ensuring that the finished product not only meets customer expectations but also complies with industry guidelines. With real-time data accessibility and structured Engineering Change Management procedures, potential flaws can be detected and corrected before they escalate into costly problems.

3. Faster time to market

PLM software accelerates the product development process by improving communication and streamlining workflows. Team members across various departments can collaborate in real time, ensuring that projects move smoothly from one stage to the next.

With faster prototyping, improved supply chain coordination , and reduced lead times, companies can launch products sooner, giving them an edge in rapidly changing markets.

4. Reduced costs

Reduced material costs and inventory value: With PLM, businesses have better data to optimize inventory management, thus minimizing overstock and cutting down on material wastage.

Fewer delays and rework in production: By fostering clear communication and real-time data sharing, PLM eliminates costly production delays. Errors originating from outdated information or design miscommunication can be avoided, resulting in significant savings.

Improved productivity: Automating repetitive tasks, effective change management, and centralized information sharing translate into increased operational productivity. Employees can focus on strategic initiatives rather than administrative burdens, further driving cost efficiency.

5. Drive innovation and growth

Innovation thrives when there’s an environment of collaboration and shared knowledge. PLM software encourages creativity by giving teams the tools to experiment, analyze, and improve ideas rapidly. By leveraging insights from past projects, businesses can foster a culture of continuous improvement and push the boundaries of innovation. People need to spend less time on repetitive and manual tasks and can focus on innovation and actual design work instead.

6. Improved decision-making

A PLM system consolidates product information in one accessible platform, empowering decision-makers with real-time data. With accurate insights readily available, businesses can make well-informed decisions that are aligned with both short- and long-term objectives.

With PLM software, decision-making becomes more reliable and efficient as teams can trust and easily access accurate product data. The centralized system eliminates guesswork and provides a single source of truth for all product-related information. When considering engineering changes or new product initiatives, decision-makers can quickly access historical data, current product performance metrics, and resource availability. This comprehensive view enables confident decisions based on reliable data rather than assumptions.

7. Reduce risk

Risk management is another area where PLM excels. With comprehensive data visibility and automated compliance monitoring, companies can identify potential issues before they escalate. By standardizing processes, businesses can mitigate risks associated with product recalls and non-compliance.

8. Effective quality and regulatory compliance management

Staying compliant with industry regulations can be a challenging task, but PLM software simplifies this process. With PLM, you can ensure that the entire organization follows consistent workflows and processes while meeting the quality targets and standards established for operations.

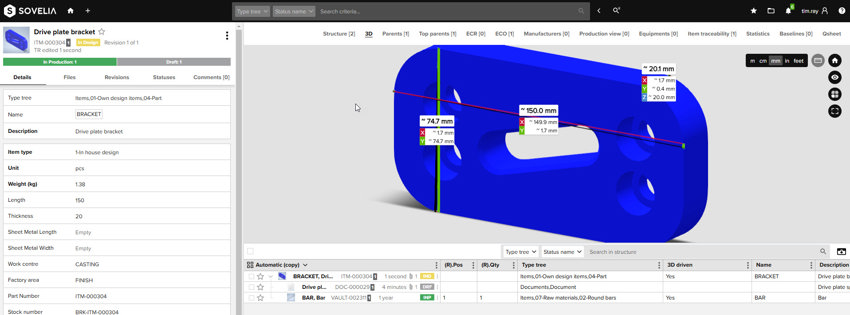

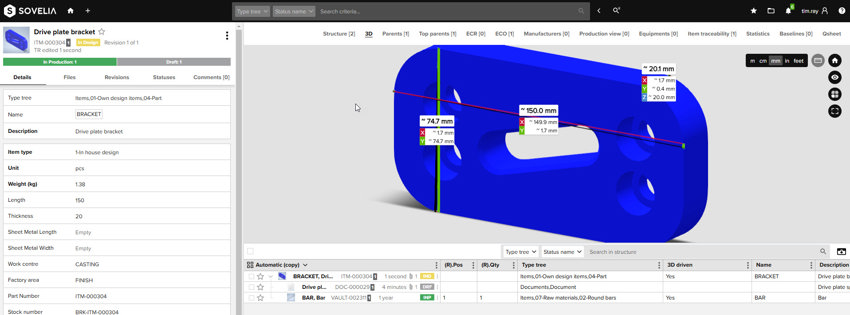

9. Increased visibility of project progress

Transparency is critical for effective project management. With PLM, stakeholders gain real-time visibility into the status of ongoing projects. Dashboards, milestone tracking, and reporting tools provide a clear picture of progress, helping teams identify potential bottlenecks and resolve them swiftly.

This visibility ensures that every team member stays aligned, contributing to a smoother development process and more predictable outcomes.

Also, with a solid PLM system, you can see the whole project in one place, whether it’s about items and structures, project documentation or production status.

10. Improved client experience

Ultimately, the end goal is to satisfy customers, and PLM software plays a crucial role here. By streamlining processes and enhancing product quality, businesses can offer superior customer experiences. On-time deliveries, higher-quality products, and the ability to respond quickly to customer feedback ensure that clients remain loyal and satisfied.

What is the value of PLM?

A Product Lifecycle Management (PLM) system provides value across various departments by centralizing product information and streamlining processes.

For the engineering team, PLM ensures efficient access to accurate designs, items, and bills of materials (BOMs), enabling reuse and fostering collaboration across disciplines such as mechanical, electrical, and software engineering.

With PLM, you can:

- Automate workflows such as Engineering Change Management

- Enhance communication through a single source of truth, and

- Integrate seamlessly with CAD and ERP systems, reducing errors and manual data entry.

This allows engineers to focus more on innovation while improving the overall quality and efficiency of design and engineering processes.

For sales, PLM integration with Configure-Price-Quote (CPQ) tools accelerates and enhances the creation of accurate quotes for complex products, ensuring manufacturability through rule-based configurations. It streamlines the sales process by:

- Providing immediate access to reliable product data

- Facilitating quick responses to customer inquiries, and

- Enabling error-free pricing and quotations.

Beyond sales, production, purchasing, and after-sales teams benefit from up-to-date product information, standardized components, effective communication of changes, and optimized inventory management. By maintaining complete lifecycle data, a PLM system supports maintenance, spare parts tracking, and service planning, allowing companies to maximize service potential and improve customer satisfaction.

What is the impact of PLM?

Adopting PLM significantly enhances business performance by increasing efficiency, improving product quality, and fostering innovation. Centralizing product information and automating workflows allow teams to spend less time on repetitive tasks and more time on value-adding activities.

PLM improves collaboration and streamlines processes which leads to:

- less errors,

- accelerated product development, and

- faster time-to-market.

Additionally, systematic change management and real-time data sharing help maintain high product quality by preventing costly design errors and addressing issues before they escalate. These benefits enable companies to meet regulatory standards seamlessly while reducing production costs, minimizing waste, and optimizing inventory.

PLM also drives strategic growth by empowering teams to innovate and expand into new markets. Decision-makers benefit from reliable insights provided by a single source of truth for product data, enabling more informed and confident planning.

Additional impacts of PLM are:

- Enhanced visibility into project progress ensures alignment across stakeholders, avoiding bottlenecks and maintaining momentum.

- By reducing risks, ensuring regulatory compliance, and delivering higher-quality products, PLM contributes to an improved customer experience.

- With faster deliveries, greater responsiveness to feedback, and consistent quality, businesses gain customer trust and loyalty, setting the stage for sustainable growth and competitive advantage.

Learn more: How ETO and CTO companies can benefit from PLM

What is the main objective of PLM?

The main objective of Product Lifecycle Management (PLM) is to provide a centralized system for managing all product-related information throughout its entire lifecycle, from ideation and design to production, sales, and after-sales service. PLM aims to enhance efficiency, foster cross-departmental collaboration, and streamline processes by ensuring that accurate, real-time data is accessible to all stakeholders.

By automating workflows, minimizing errors, and optimizing resource use, PLM supports businesses in delivering high-quality products faster and at lower costs. It also facilitates innovation, drives informed decision-making, ensures regulatory compliance, and mitigates risks, ultimately improving customer satisfaction and enabling sustainable growth.

Why choose PLM?

Choosing PLM boosts efficiency, collaboration, and product quality by centralizing information and eliminating data silos. Teams spend less time searching for data and more on innovation, supported by automated workflows, streamlined processes, and real-time data sharing, which increase productivity and reduce errors.

PLM enhances decision-making with accurate, up-to-date information and ensures compliance, risk reduction, and efficient change management. It helps deliver high-quality products faster and at lower costs, while fostering innovation, improving customer satisfaction, and supporting sustainable business growth in competitive markets.

Why choose Sovelia Core PLM system?

Choosing Sovelia Core PLM for your business offers a wide range of benefits to optimize your operations, improve collaboration, and enhance product quality. Sovelia Core PLM centralizes product information, ensuring seamless communication and eliminating data silos across your organization. By providing real-time access to accurate data and automating workflows, Sovelia Core helps your teams focus on innovation and value-adding activities instead of repetitive tasks, driving efficiency and productivity.

With Sovelia Core, you can translate your CAD data into items and BOMs, share them with the rest of the organization, and integrate product information with ERP.

Are you interested to learn more about how PLM can benefit your business?

Our team is here to help! Contact us today.